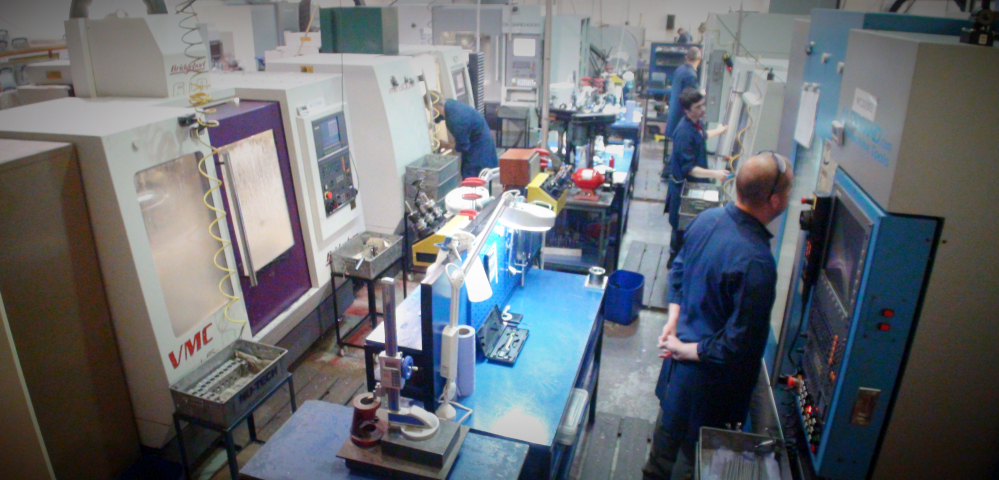

Over the years we have made substantial investments in the latest CNC milling and machining centres, accompanied with the most up to date work holding devices and tooling. This continual investment has enabled us to offer a cost effective machining service whilst maintaining the highest quality standards.

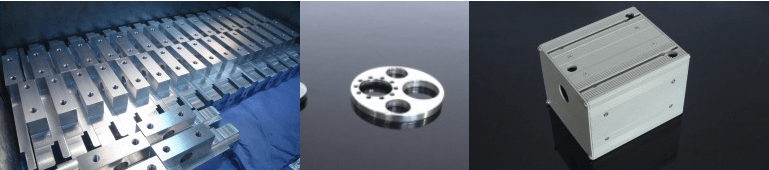

Our extensive CNC turning and milling capabilities put us in a good position to provide a fast turn around for precision machined components and turned parts in most materials. They include: Aluminium, Brass, Stainless Steel and a wide range of Plastics.

Our milling section is equipped with the following types of machinery:

Qty. CNC Machining Centres. Component size up to 1020mm x 600mm x 500mm

- 1 Dugard Eagle 1000 VMC. 24 tool stations with 10,000 rpm spindle speed capacity and indexing capability.

- 1 Dugard Eagle 850VMC. 24 tool stations with 10,000 rpm spindle speed and 4th Axis capability.

- 2 Dugard Eagle 660 VMC. 24 tool stations with 10,000 rpm spindle speed capacity. (one with indexing capability and one with 4th Axis capability).

- 3 Bridgeport VMC 600 CNC. 22 tools stations with fourth axis capability, one with 8,000 rpm spindle speed capacity and two with 12,000 rpm spindle speed capacity.

Qty. CNC Light Milling and Drilling Centres

- 1 Sykes T14iA Robodrill. Fanuc control with 14 tool stations.

- 1 Sykes T14iB Robodrill. Fanuc control with 14 tool stations.

Compatibilities Include:

Machining Envelopes of up to 1020 mm (X) x 510 mm (Y) x 500 mm (Z)

Fourth Axis Machining

Supported By:

The Latest Pathtrace 3D CAD/CAM System

To receive further information or a quotation, please contact us.